Vibra-Screen Separators

Product Series

Product Description

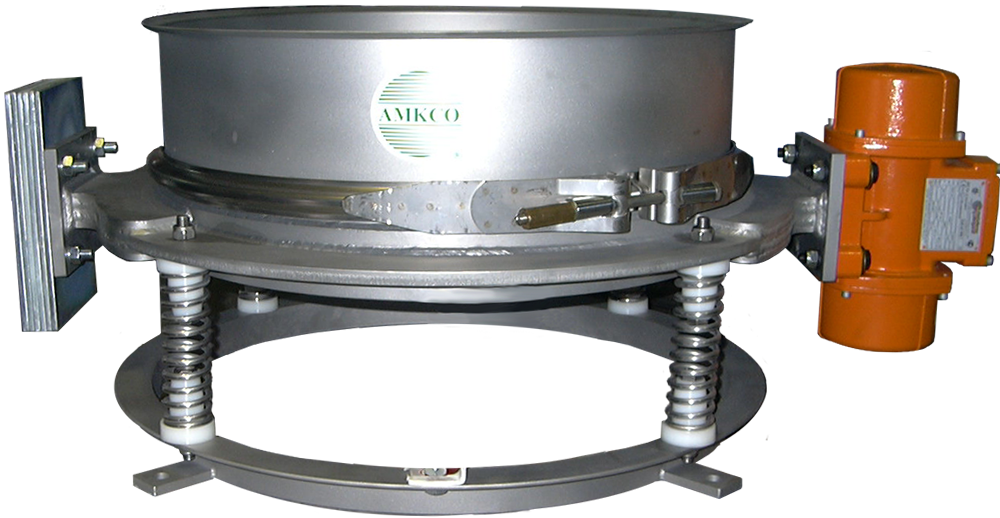

Vibra-Screen

High efficiency circular vibratory separators in 8 sizes from the 18" diameter laboratory / production unit to the 84" diameter machine that is redefining even higher capacity and reliability standards.

Creative design features: maximize screen area use, handle varying feed rates, screen materials of changing consistencies, increase the "unders" or "overs" capacities, and prevent screen blinding.

One to five screen surfaces yielding up to six predetermined fractions with accurate separations in mesh sizes from 2" down to 25 micron (500 mesh).

Questions? See the catalog or get in touch.

Product Description

Air Tight Separator

Designed for screening in pneumatic conveying systems. Primarily for in- line scalping of dry, free-flowing materials.

Assures efficient removal of oversized particles and foreign materials during loading or unloading of tank trucks and rail cars, or while conveying materials to storage or process.

Six sizes from 24" diameter to 72" diameter with stainless steel on all product contact surfaces.

Questions? See the catalog or get in touch.

Product Description

Auxiliary Series

Auxiliary series feed frame to increase screen area by up to 70 percent within the same frame height. Applied to increase efficiency of a separation or increase throughput. Sizes come in 60" diameter and 72" diameter.

Questions? See the catalog or get in touch.

Product Description

Batch Sifter

Batch dry sifting or wet filtering requires a simple, economical design that does not require continuous discharge of the oversize material.

The 18" diameter or 24" diameter models have only one vibrating motor (electric or air) mounted vertically to impart horizontal motion. Designed for intermittent or continuous operations where occasional but fast separations are needed.

Portable or stationary, commonly used above a mixer or bag dump station.

Questions? See the catalog or get in touch.

Product Description

Straight-Flo Separator

The AMKCO Straight-Flo separator offers high capacity wet or dry trash screening / scalping in a low profile and compact design. Twin vibrator motors mounted externally 180 degrees apart allow required headroom to be reduced considerably, making for easy in line installation in existing process lines, where overhead space is at a premium, and on-size product drops directly down to the next process.

High volume scalping requires a design where the material moves quickly through the screen and out of the separator. The innovative "Straight-Flo" design allows the bottom outlet to be located directly beneath the top inlet enabling screened material to pass straight through the machine at very high rates.

Recommended for high volume dry scalping or high volume wet filtering. Available in all model sizes. 8 sizes from 18" diameter to 84" diameter.

Questions? See the catalog or get in touch.

Product Benefits

AMKCO Vibra-Screen Separators brings profitable solutions to your process problems.

New Food Products

New food products were made possible with ultrasonic application to the screen. The material would not otherwise have processed at the required screen mesh. Now, the end product is unique with fast pay back to the producer.

High Capacity In Limited Space

High capacity in limited space is required by palm oil producers. Twenty hour days over a hot oil tank at 98°C require a high degree of reliability in a cramped environment.

No Transmitted Vibration

This was a need for a dairy and juice producer. The AMKCO separator is mounted on a portable stand, easily movable to different locations for different products. The various locations have floors that are not always level. Quick and easy shims under the legs keep the screen level for good separation.